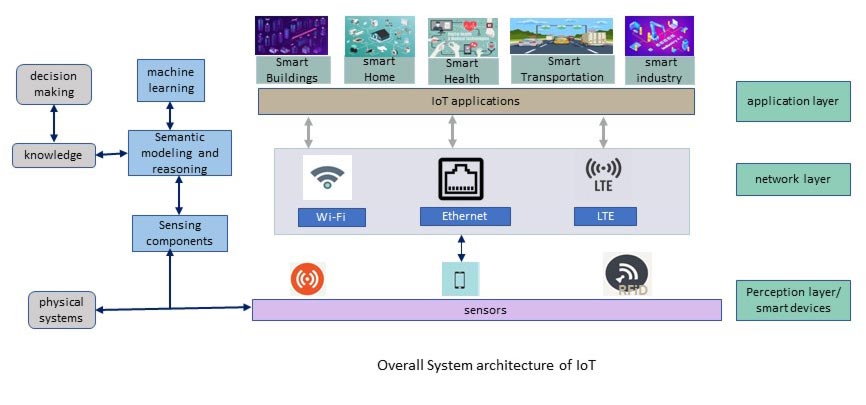

The overview of IoT architecture is mentioned below.

The overall system architecture of IoT is shown here. The first layer is the perception layer or smart devices layer. The sensors are communicated using RFID, a mobile app to the network layer. IoT applications run above the network layer. The network layer can have WI-FI, Ethernet, or LTE protocols. The IoT applications include smart industry, smart health, smart home, etc

Benefits

- Cost reduction can be minimized using IoT in smart manufacturing. Some of the benefits are:

- Help into the forecasting of inventory requirements

- Reduction of maintenance costs

- Operations With minimized error

- Increase efficiency of staffing

- Smart manufacturing using IoT makes it easier for manufacturers to monitor:

- Monitoring of factory assets

- Ease to monitor inventory and stocks

- Maintain a quality level of materials

- Observe employee efficiency

- All over the monitoring of manufacturing facilities

- The sensors can help manufacturers to find faulty components and replace them.

- Using IoT and advanced algorithms, the manufacturer knows the fault before it occurred. The forecasting of maintenance requirements in the advance notification and the preventing mechanical failure and stoppages possible.

- IIoT can be used to send commands to machines. According to the command, the machine performs the task and gives the required results.

- Using IIoT in smart manufacturing, it can:

- Reduction of unplanned downtime

- Reduction of waste

- Reduced maintenance

- Increase the quality of outputs as per requirements

- Extend life-cycle of machines

- Increase the transparency across the manufacturing process and reduced human error. Also, prevent accidents and ensure the safety of workers.

Challenges

- The biggest concern of IIoT in manufacturing is the lack of industry-wide standards.

- The interoperability is poor and for implementation of new hardware and processes is costly.

The below criteria are challenges:

- Need to integrate technology into existing workflow

- Required to set-up complex IT infrastructure and processes

- Evolve new cross-functional collaboration

- Using service provider infrastructure, the reliability of data goes down. Also, the manufacturer can be a dilemma of ownership.

- Due to more networked devices, the cybersecurity concern may arise.

Future Scope of IIoT in Manufacturing

- IIoT helps in manufacturing to boost revenues by increasing production

- Over the years, the manufacturing cost would be decreased by adopting IIoT

- Easy to achieve new growth approaches and reduced all over man work-force

- Using customized applications or software, the manufacturer can minimize internal and external compatibility issues.

The new technology is evolving in the manufacturing domain. Using IoT in manufacturing, better performance and high-accuracy can be achieved. The manufacturing sector uses the sensors and new processes with less human intervention. Yes, there are some challenges to adopt IoT in manufacturing. In near future, these challenges can be overcome with better security and reliability.